Flooring Plant Concrete

Heavy Industrial Construction Under Time and Space Constraints

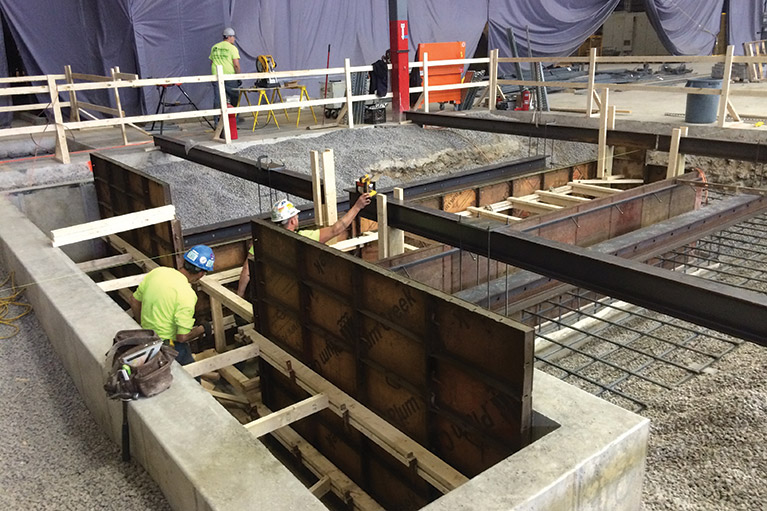

Yoe was tasked with replacing the concrete pits and foundations at multiple locations within an operating flooring plant with a strict 6-week deadline to prepare for the installation of new equipment.

Challenge

Construction within an existing facility can present challenges as work needs to be completed safely and effectively around the building’s employees and not impact work production. Yoe was awarded a heavy industrial construction project at a large fully integrated flooring operation in western Pennsylvania that required a variety of services, skills and teamwork while being conscious of surroundings, on a tight budget and a 6-week deadline.

Equipment for the flooring plant was shipped from overseas and arrived ahead of schedule. Since this presented limited workspace and concrete trucks couldn’t fit in, Yoe’s team set up concrete pumps and were still able to precisely complete the project with the equipment stored throughout their work area.

Services & Solutions

To ensure the protection of the facility’s employees, Yoe put up a 600-lineal-foot fire-retardant curtain upon arrival at the jobsite before the start of any construction. Key aspects of the project included:

- Demolition & Excavation

Demolition included sawing and removing 300 tons of the existing concrete floor and excavating 1,000 cubic yards of ground from the start of excavation for four different pits: cooling table, loading table, cable feed pit and press foundation. A critical part of the project was the arrival of a 100-ton press from overseas. From the start of excavation to setting the press, Yoe had 3 weeks to excavate, form, place steel, pour concrete and allow cure time in preparation for the arrival of the equipment. - Concrete Pits and Foundations

Stone bases were replaced; 25 tons of rebar went into the foundation and areas were boxed out for rails. The experienced team prepped, poured, and finished all four pits, including setting 500 lineal feet of steel rail. In total, 500 cubic yards of concrete were used for the pits and foundations. - Exterior Work

Upon finishing the interior construction, exterior work included installing a dust collector and dust transfer system foundations. - Staffing

Yoe’s dedicated crews were scheduled to overlap to allow for construction to keep moving, with communication being key. While offering budget savings opportunities throughout the entire process, Yoe worked efficiently with the flooring operation’s owner to work around the clock to complete the project prior to the 6-week deadline.

Results

Both the general contractor and client were very pleased with Yoe’s commitment to producing quality construction.